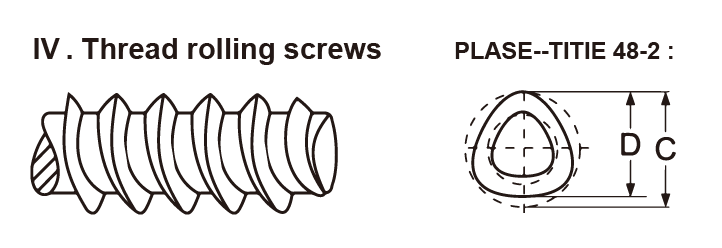

Thread Rolling Self-Tapping Screw

Product Introduction

Thread Rolling Self-Tapping Screw

Trilobular thread rolling screw with extra wide spacing between 48。 profile threads, twin lead threads with a 1-2 thread point taper.

Applications/Advantages:

Thermoplastics engineering resing and certain thermosets. Sharper thread profile increases holding strength while reducing material displacement. Drive and strip torques are higher, reducing the need for inserts or reinforcing clips.

| THREAD ROLLING SCREWS | |||||||

| Nominal Screw Size and Threads Per inch | c | D | Minimum Out-of-Round | Recommended Pilot Hole Sizes | |||

| Diameter of Circumscribing Circle | Measurements Across Center | ||||||

| Max | Min | Max | Min | Soft Ductils Materials | Brittle Materials | ||

| 4-20 | .127 | .120 | .123 | .117 | .002 | .100 | .106 |

| 6-19 | .147 | .141 | .143 | .137 | .003 | .122 | .128 |

| 8-16 | .185 | .179 | .179 | .173 | .004 | .149 | .158 |

| 10-14 | .212 | .206 | .208 | .202 | .004 | .175 | .185 |

| 1/4-10 | .276 | .270 | .268 | .262 | .006 | .224 | .240 |

| Tolerance on Length | Thru 3/4" : ±.030" | Over 3/4" : ±.050" | |||||

| Description | Trilobular thread-rolling screw with extra wide spacing between 48° profile threads : twin lead threads with a 1-2 thread point taper. |

| Applications/Advantages | Thermoplastics engineering resins and certain thermosets . Sharper thread profile increases holding strength while reducing material displacement. Drive and strip torques are higher,reducing the need for inserts or reinforcing clips. |

| Material | AISI 1022 steel |

| Heat Treatment | Screws shall be quenched in liquid and then tempered by reheating to 850°F minimum. |

| Case Hardness | Rockwell C45 minimum. |

| Case Depth | No.4 & 6 diameters : .002 - .007 / No.8 & 10 diameters : .004 - .009 / No.14 diameters : .005 - .011 |

| Core Hardness (after tempering) | Rockwell C28-38 |