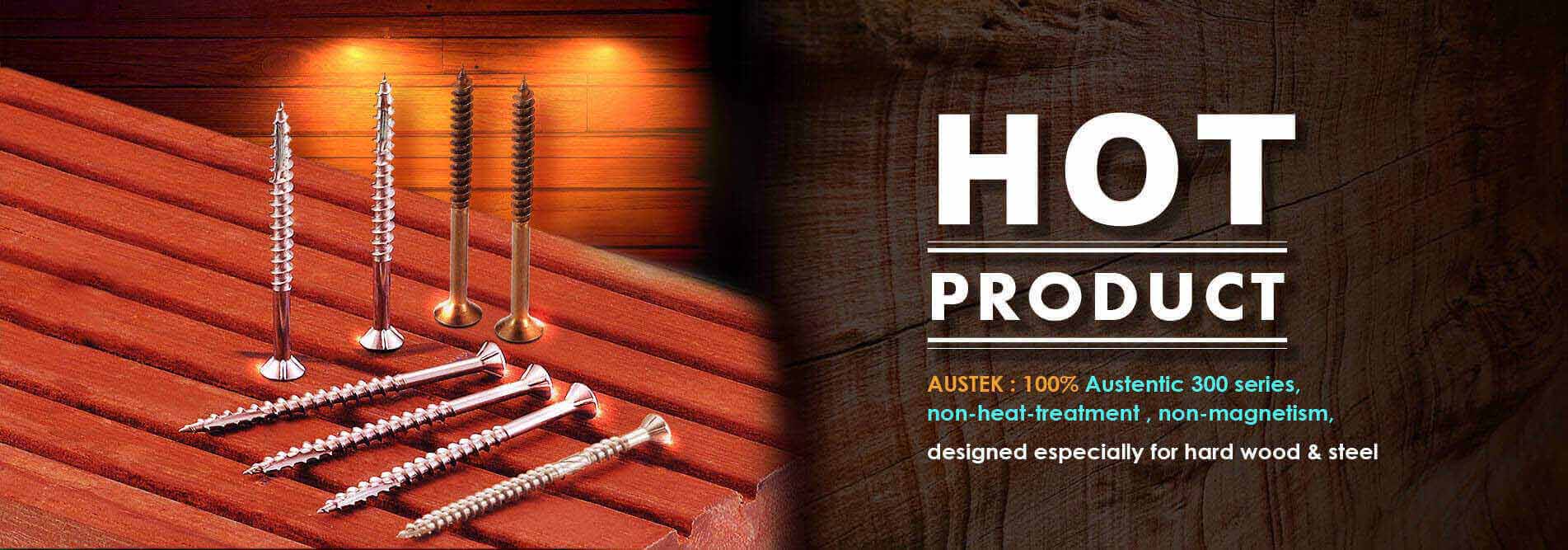

AUSTEK - Decking Screw

Every kinds of accreditation and patent certification.

The advantages of AUSTEK

Samples : #8 screw WIRE 3.30 mm

| ITEM / PART | AUSTEK | 410 SS | 302 HQ | C1022 STEEL |

|---|---|---|---|---|

| TORQUE( kg/cm ) | 63 63 62 63 63 | 76 78 77 77 78 | 40 40 41 42 40 | 69 70 68 72 72 72 |

| CASE HARDNESS( HV ) | 380 - 390 | 674 - 726 | 380 - 390 | 613 - 641 |

| CORE HARDNESS( HV ) | 376 - 384 | 400 - 420 | SOFT | 400 - 430 |

| CORROSION TEST | EXCELLENT | SO-SO | GOOD | 24HRS(Ref.) |

| SHEAR(kgf) | 1261 | -- | -- | -- |

| MAGNETISM | X | V | X | V |

| DRILLING PLATE THICKNESS | 2mm (Max.) | 1.58-1.73mm | X | 1.58-1.73mm |

| HARDEN | UNHARDEN | HARDEN | UNHARDEN | HARDEN |

The advantages of AUSTEK

- NO CARBURIZATION

- NO NEED PRE-DRILLING HOLE

- HIGH TENSILE / HIGH TORQUE/ HIGH SECURITY

- HIGH ANIT-CORROSION

- NON MAGNETISM

- NO EMBRITTLEMENT

- ACQ TREATED-WOOD COMPLIANCE

RE: 2008 REVOLUTION -New Technology – SUS300 SERIES

Characteristic :

- 100% Austentic 300 series, high torque and strength,no heat-treatment, non-magnetism, meet ACQ or RoHS compliant,

- no hydrogen embrittlement, excellent corrosion resistance, competitive pricing

Getting it over and done! From now on!

| AUSTEK | 410SS | C1022 | |

|---|---|---|---|

| HARDEN | X | V | V |

| Magnetism | X | V | V |

| Corrosion | GOOD | NG | NG |

| Torque | Per IFI or DIN | ditto | ditto |

- PARTICLE BOARD SCREW Torque strength

- CHIPBOARD SCREW Torque strength

- TAPPING SCREW Torque strength

- #8 -10 Wire 3.05 ave. : 45(kg-cm) = 39 In-lbs

- #10 -9 Wire 3.60 ave. : 75(kg-cm) = 65 In-lbs

- #M4.0-P1.80 Wire 2.80 ave. : 36(kg-cm) = 31 In-lbs

- #M5.0-P2.20 Wire 3.45 ave. : 65(kg-cm) = 56 In-lbs

- #8 -18 Wire 3.30 ave. : 59(kg-cm) = 51 In-lbs

- #10 -16 Wire 3.80 ave. : 91(kg-cm) = 79 In-lbs

AUSTEK,100% 300

- 2008 NEW ARRIVAL, REVOLUTION IN SUS 300 SERIES PENERATE

- NO MORE SUFFER IN THE RUST, AUSTEK,100% 300 SERIES SLOVE IT!

- UNIQUE “ & THE NO 1. DRILLING ABILITY

The patent AUSTEK is made of SUS 300 series,”NO CARBURIZATION” , because HEATING , which resulted in the stainless steel lost its properties, WITHOUT HEAT-TREATMENT but keep the chemical compounds consistently till finished with high torque, even penetrating the thin steel plate as well as low carbon steel doing well, designated for very hard wood application especially, which compared the difference to the normal stainless steel disadvantage of soft.

Therefore, Austek is the best choice to eliminate red rust, high anti-corrosion, meet ACQ or RoHS compliant, specified worldwide in all the applications of interior or outdoor.

- STEEL PLATE THICKNESS : 2mm OR 1.5mm X 2

- Recommended screwgun : 1000 RPM

SPECIFICTION:

- FINISH : ELECTRO ZINC PLATED & WAX

- CORROSION TEST : 500 HRS PER ASTM B-117

- KESTERNICH TEST : 15 CYCLES PER DIN50018

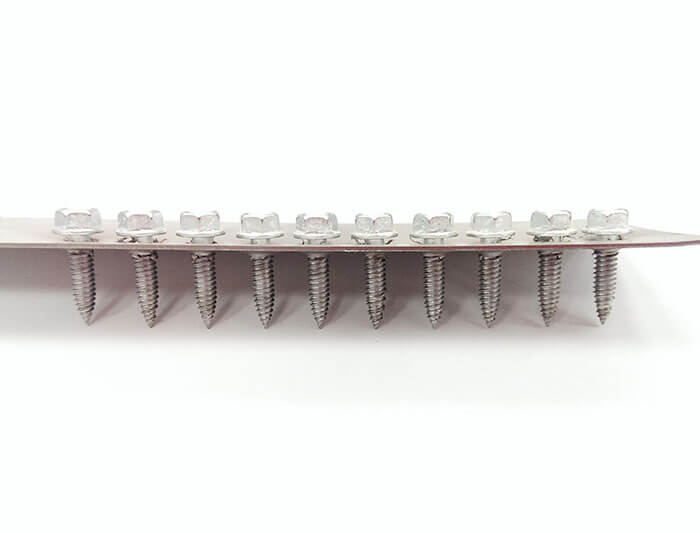

SCBM STAR CONNECTION BI-METAL

LINK-ASSEMBLY, NOT WELDING., NO HEAT-TREATMENT,

THE GENUIE”COLD-FORGED” **STAINLESS STEEL + CARBON STEEL**

SCBM is a new and pending patent. It totally overturns the traditional welding processing originally, most stainless that is “hardened” has to be treated as to welded. However, “SCBM” is without carburization, the original properties of the stainless remain 100% intact, but the genuine “cold-forged”, the failure rate is approximately under 1%.

NOTE:

- WITH OR WITHOUT EPDM BONDED WASHER FOR IHWH, FLANGE

- NOTE : #5 POINT TAP UP TO 12 mm

SIZE:

- #10-16X1 ~ 3” #3PT

- #12-14X1 ~ 4” #3PT

- 1/4-14X1 STICH POINT #1 PT

- 1/4-14X1 STICH POINT #1 PT

- 1/4-14X1~6” #3PT

- 5.5X25 #3PT

- 5.5X35 #3PT/#5PT

- 5.5X50 #3PT/#5PT

- 5.5X60 #3PT/#5PT

- 5.5X80 #3PT/#5PT

- 5.5X100~ 200 #3PT/#5PT

- COMPOSITE PANEL/SANDWICH SCREW/DOUBLE THREAD

- WITH OR WITHOUT EPDM BONED WASHER

- 5.5/6.3X60 #3PT/#5PT

- 5.5/6.3X80 #3PT/#5PT

- 5.5/6.3X105 #3PT/#5PT

- 5.5/6.3X125 #3PT/#5PT

- 5.5/6.3X135 #3PT/#5PT

- 5.5/6.3X150 #3PT/#5PT

- FINISH : ELECTRO ZINC PLATED & WAX

- CORROSION TEST : 500 HRS PER ASTM B-117

- KESTERNICH TEST : 15 CYCLES PER DIN50018

- HIGH TQRQUE STRENGTH

| #6-20 | #8-18 | #10-16 | #12 | #1/4 |

|---|---|---|---|---|

| 38 | 52 | 91 | 145 | 219 |

SAFE 300 10.9 CLASS

OVERTURN THE PROPERTY OF STAINLESS STEEL IN YOUR IMAGINE, SAFE 300, “NO HEAT-MENAT” HIGH TENSILE/ HIGH TORQUE, HIGH SECURITY, HI ANTI-CORROSION, EQUALLY TO CLASS 10.9 IN ALLOY STEEL, BUT IT’S MADE OF SUS 300 SERIES.NON-MAGNETISM, NO EMBRITTLEMENT, NO CONTAMINATION.

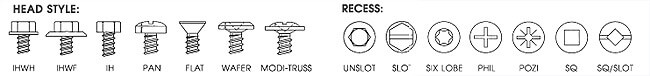

Design from customer is welcomed!