SEMS SCREW

Product Introduction

SEMS(TAPPING) SCREW :

SEMS combines two normally seperate parts-typically a screw and a washer- into one permanently pre-assembled cost saving component. Washers are hel in place under the screw head by the rolled threads; they will not fall off and are free to rotate.

ADVANTAGES :

- SPEEDS: PRODUCTION BY ELIMINATING HARND ASSEMBLY AT THE WORK STATION

- PERMANENT : CAPTURING OF WASHER INSURES THAT IT WILL NEVER COME OFF OR BE LEFT OFF YOUR ASSEMBLY

- ADAPTS EASILY TO AUTOMATED FEEDING DEVICES AND DRIVING TOOLS

- AVAILABE IN ANY COMBINATION OF SCREW TYPE, HEAD STYLE, WASHER AND THREAD CONFIGURATION

- PRODUCTION RANGE : M2.5 ( #2) ~ M 12 ~ (1/2" . LENGTH : 4mm (5/32" ) ~ 160mm (6")

- ISO 9001 CERTIFICATED MANUFACTURER & EXPORTER*

Screw and washer assemblies-SEMS, DIN6900

- Included in these specifications are SEMS comprised of the following types of screws and washers :

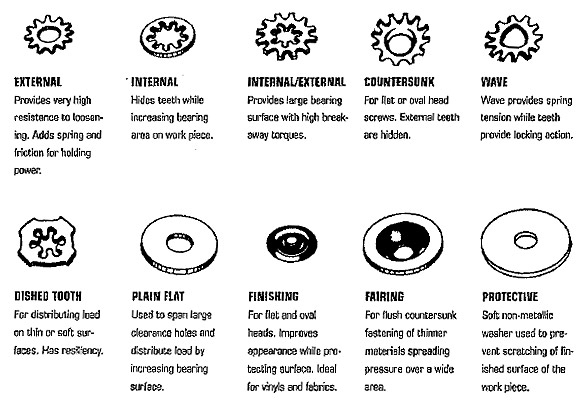

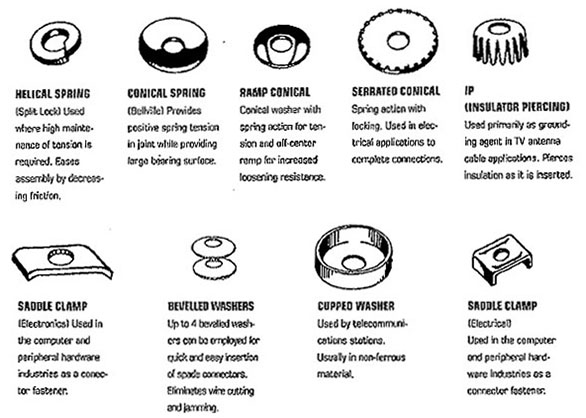

- (a) Helical Spring Lock Washers.

- (b) Tooth Lock Washers

- (c) Conical Spring Washers

- (d) Plain Washers

- (e) By the purchaser’s drawing or standard

Screw and washer assemblies

- Coarse threaded Screws with captive plain washer

- DIN6900

- Examples of screw and washer assemblies

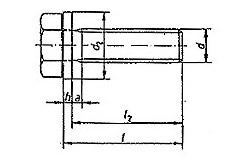

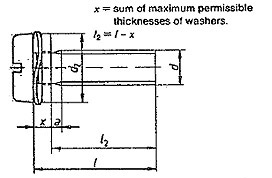

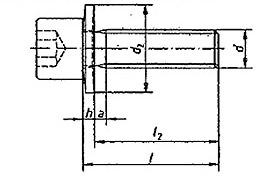

Figure 1. Assembly with screw threaded approximately up to the head.

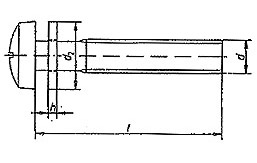

Figure 2. Assembly with screw unthreaded portion of shank.

Screw and washer assemblies

- Coarse threaded Screws with captive curved spring lock washer

- DIN6900

- Examples of screw and washer assemblies

- Table 1. DIMENSIONS

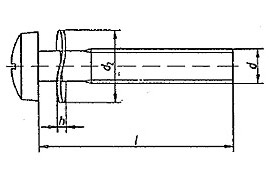

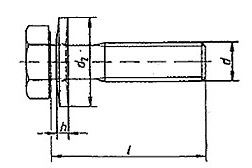

Figure 1. Assembly with screw threaded approximately up to the head.

Figure 2. Assembly with screw unthreaded portion of shank.

| Thread size (d) |

a | / 2" | Washer dimensions DIN 6907 washer |

|

| Type C (7) |

||||

| h | d2 | |||

| max | min | » | ||

| M2.5 | 0.9 | 4 | 1.2 | 5.5 |

| M3 | 1 | 4 | 1.2 | 6 |

| (M3.5) | 1.2 | 6 | 1.5 | 7 |

| M4 | 1.4 | 6 | 1.5 | 8 |

| M5 | 1.6 | 6 | 1.8 | 9 |

| M6 | 2 | 8 | 2.1 | 11 |

| M8 | 2.5 | 10 | 2.4 | 14 |

| M10 | 3 | 12 | 2.7 | 18 |

| Use of the size give in brackets should be avoided where possible. 1) / 2min is the smallest effective screw length manufacturable. | ||||

| See relevant product standards for specifications for /. | ||||

Screw and washer assemblies

- Coarse threaded Screws with captive curved spring lock washer

- DIN6900

- Examples of screw and washer assemblies

- Table 1. DIMENSIONS

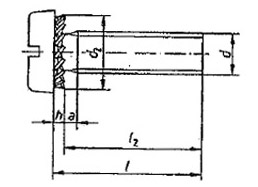

Figure 1. Assembly with screw threaded approximately up to the head.

Figure 2. Assembly with screw unthreaded portion of shank.

|

Thread size (d) |

a | / 2" | Washer dimensions DIN 6907 washer |

|

| Type C (9) |

||||

| h | d2 | |||

| max | min | max | ||

| M2.5 | 0.9 | 4 | 0.72 | 6 |

| M3 | 1 | 4 | 0.85 | 7 |

| (M3.5) | 1.2 | 6 | 1.06 | 8 |

| M4 | 1.4 | 6 | 1.3 | 9 |

| M5 | 1.6 | 6 | 1.55 | 11 |

| M6 | 2 | 8 | 2 | 14 |

| M8 | 2.5 | 10 | 2.6 | 18 |

| M10 | 3 | 12 | 3.2 | 23 |

| M12 | 3.5 | 14 | 3.95 | 29 |

| Use of the size give in brackets should be avoided where possible. 1) / 2min is the smallest effective screw length manufacturable . | ||||

| See relevant product standards for specifications for /. | ||||

Tapping screw and washer assemblies

- DIN6901

- Type C (with cone point)

- Type F (with blunt end)

- Table 1. Dimensions

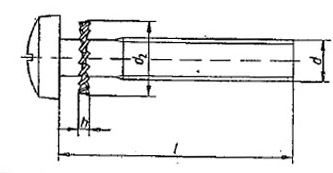

Figure 1. Assembly with screw threaded approximately up to the head.

Figure 2. Assembly with screw unthreaded portion of shank.

| Thread size | / 1 " | a | Washer dimensions DIN 6903 curved spring lock washer |

|||

| Type A(1) | Type B(2) | |||||

| min | max | h | d2 | h | d2 | |

| ST2.9 | 5.5 | 1.1 | 1 | 7 | 1 | 9 |

| ST3.5 | 8.5 | 1.3 | 1 | 8 | 1 | 11 |

| (ST3.9) | 8.5 | 1.3 | 1 | 9 | 1 | 12 |

| ST4.2 | 8.5 | 1.4 | 1 | 9 | 1 | 12 |

| ST4.8 | 11.4 | 1.6 | 1 | 10 | 1.6 | 15 |

| ST5.5 | 11.4 | 1.8 | 1.6 | 12 | 1.6 | 15 |

| ST6.3 | 11.4 | 1.8 | 1.6 | 14 | 1.6 | 18 |

| (ST8) | 14 | 2.1 | 1.6 | 16 | 2 | 24 |

| 1) / 2min is the smallest effective screw length manufacturable. Use of the size give in brackets should be avoided where possible. | ||||||