STAINLESS STEEL SCREW

Product Introduction

Austenitic stainless steel is one of the five classes of stainless steel as defined by crystalline structure (along with ferritic, martensitic, duplex and precipitation hardened).Its primary crystalline structure is austenite (face-centered cubic). Such steels are not hardenable by heat treatment and are essentially non-magnetic.This structure is achieved by adding enough austenite-stabilizing elements such as nickel, manganese and nitrogen.[citation needed] The Incoloy family of alloys belong to the category of super austenitic stainless steels.

AISI 200 and 300 series

ASSs are divided into 300-series and 200-series subgroups. In 300 series stainless steels the austenitic structure obtained primarily by adding nickel. In 200 series

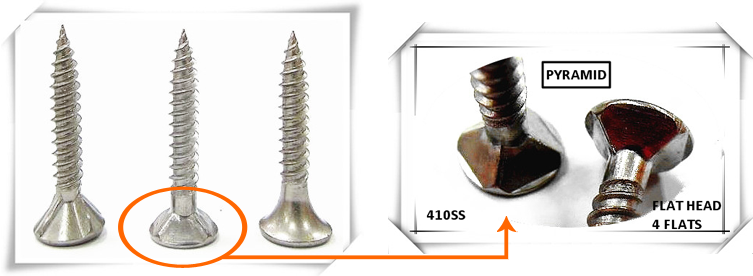

410 stainless steel is martensitic stainless steel characterized by its high strength and corrosion resistance. It is commonly used in applications that require these properties, such as cutlery, surgical instruments, and industrial equipment.

Magnetic Properties:

410 stainless steel, owing to its high iron content and martensitic structure, is typically magnetic. The martensitic structure, formed through heat treatment, gives the material its magnetic properties. However, it is important to note that the degree of magnetism may vary depending on specific factors.