Total : 0

Thread cutting screw

Thread cutting screw :

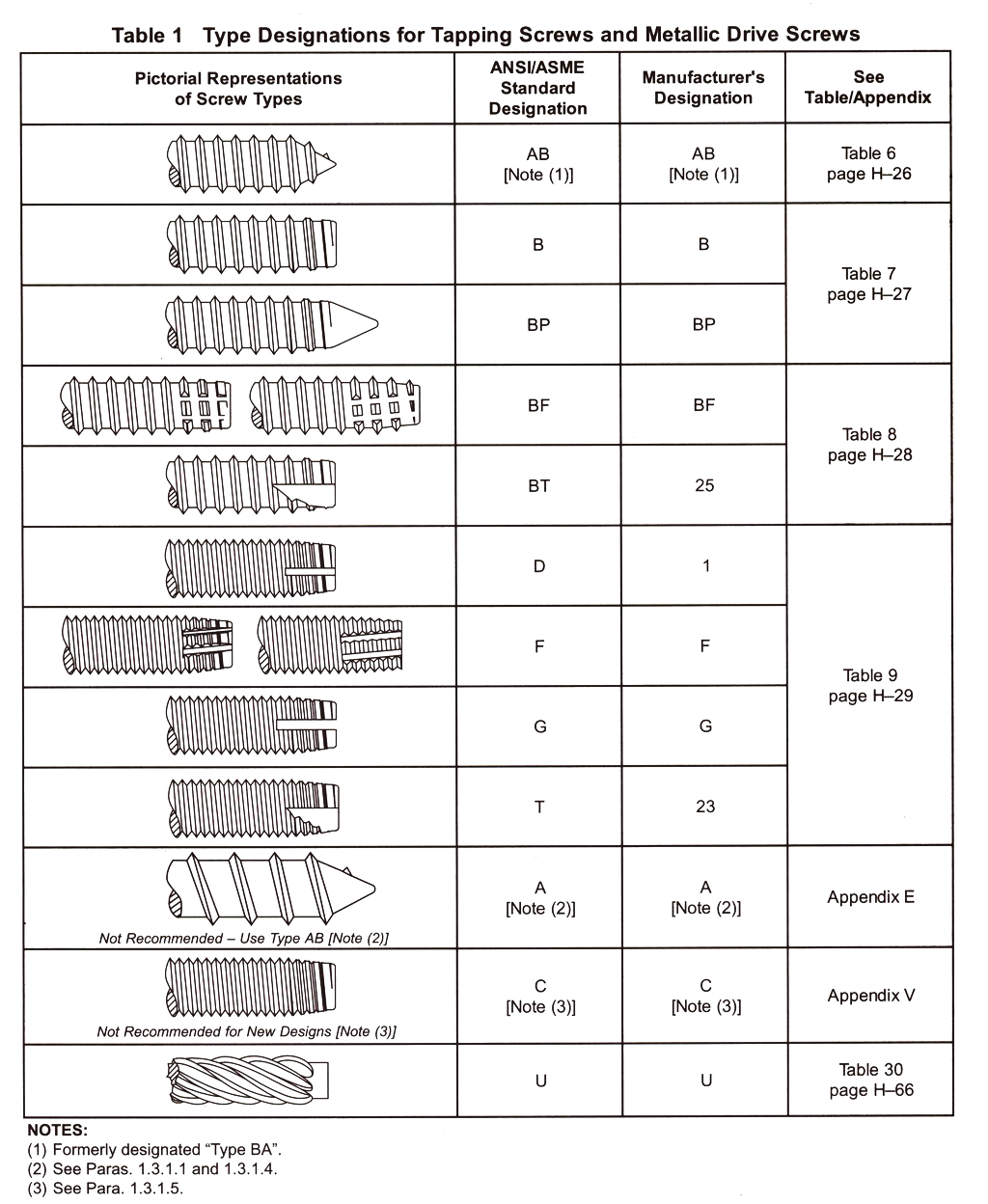

- Are Types BF, BT,, D, F, G, and T. types BF and BT have spaced threads, the other machine threads. Other differences related to the desgn of their cutting point. Before selecting a thread cutting screw, some thought should be given to the possible effect, if any, of the presence of small chips in the system.

TYPE DESIGNATIONS FOR TAPPING SCREWS AND METALLIC DRIVE SCREWS

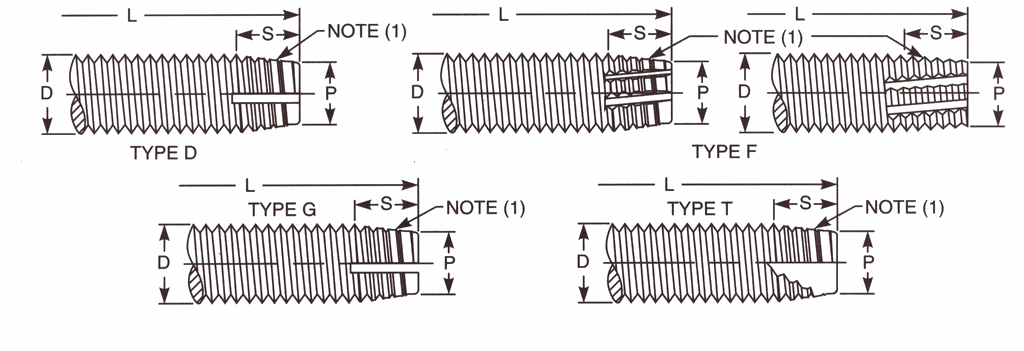

THREAD CUTTING TAPPING SCREWS-TYPES D,F,G, AND T

Table 9 Dimensions of Threads and Points for Types D, F, G, and T

Thread Cutting Tapping Screws

| Nominal Size or Basic Screw Diameter | Threads per Inch | D | P | S | L | |||||||

| Major Diameter | Point Diameter | Point Taper Length | Determinant Lengths for Point Taper | Minimum Practical Nominal Screw Lengths | ||||||||

| For Short Screws | For Long Screws | |||||||||||

| Max | Min | Ref | Max | Min | Max | Min | 90° Heads | Csk Heads | 90° Heads | Csk Heads | ||

| 2 0.0860 2 0.0860 3 0.0990 3 0.0990 | 56 64 48 56 | 0.0860 0.0860 0.0990 0.0990 | 0.0813 0.0816 0.0938 0.0942 | 0.068 0.070 0.078 0.081 | 0.062 0.055 0.073 0.062 | 0.045 0.039 0.052 0.045 | 0.080 0.070 0.094 0.080 | 0.062 0.055 0.073 0.062 | 5/32 1/8 3/16 5/32 | 3/16 3/16 7/32 3/16 | 5/32 1/8 5/32 5/32 | 3/16 5/32 7/32 3/16 |

| 4 0.1120 4 0.1120 5 0.1250 5 0.1250 6 0.1380 6 0.1380 | 40 48 40 44 32 40 | 0.1120 0.1120 0.1250 0.1250 0.1380 0.1380 | 0.1061 0.1068 0.1191 0.1195 0.1312 0.1321 | 0.087 0.091 0.100 0.102 0.107 0.113 | 0.088 0.073 0.088 0.080 0.109 0.088 | 0.062 0.052 0.062 0.057 0.078 0.062 | 0.112 0.094 0.112 0.102 0.141 0.112 | 0.088 0.073 0.088 0.080 0.109 0.088 | 7/32 3/16 7/32 3/16 1/4 7/32 | 1/4 7/32 9/32 1/4 5/16 9/32 | 3/16 5/32 3/16 3/16 1/4 3/16 | 1/4 7/32 1/4 1/4 5/16 1/4 |

| 8 0.1640 8 0.1640 10 0.1900 10 0.1900 12 0.2160 12 0.2160 | 32 36 24 32 24 28 | 0.1640 0.1640 0.1900 0.1900 0.2160 0.2160 | 0.1571 0.1577 0.1818 0.1831 0.2078 0.2085 | 0.132 0.136 0.148 0.158 0.174 0.180 | 0.109 0.097 0.146 0.109 0.146 0.125 | 0.078 0.069 0.104 0.078 0.104 0.089 | 0.141 0.125 0.188 0.141 0.188 0.161 | 0.109 0.097 0.146 0.109 0.146 0.125 | 1/4 7/32 11/32 1/4 11/32 5/16 | 11/32 5/16 7/16 11/32 7/16 13/32 | 1/4 7/32 5/16 1/4 5/16 9/32 | 5/16 9/32 13/32 5/16 13/32 3/8 |

| 1/4 0.2500 1/4 0.2500 5/16 0.3125 5/16 0.3125 3/8 0.3750 3/8 0.3750 | 20 28 18 24 16 24 | 0.2500 0.2500 0.3125 0.3125 0.3750 0.3750 | 0.2408 0.2425 0.3026 0.3042 0.3643 0.3667 | 0.200 0.214 0.257 0.271 0.312 0.333 | 0.175 0.125 0.194 0.146 0.219 0.146 | 0.125 0.089 0.139 0.104 0.156 0.104 | 0.225 0.161 0.250 0.188 0.281 0.188 | 0.175 0.125 0.194 0.146 0.219 0.146 | 13/32 5/16 15/32 11/32 1/2 11/32 | 17/32 13/32 19/32 15/32 11/16 1/2 | 3/8 9/32 7/16 5/16 15/32 5/16 | 1/2 3/8 9/16 15/32 5/8 1/2 |

| 7/16 0.4375 7/16 0.4375 1/2 0.5000 1/2 0.5000 | 14 20 13 20 | 0.4375 0.4375 0.5000 0.5000 | 0.4258 0.4281 0.4876 0.4906 | 0.366 0.387 0.423 0.450 | 0.250 0.175 0.269 0.175 | 0.179 0.125 0.192 0.125 | 0.321 0.225 0.346 0.225 | 0.250 0.175 0.269 0.175 | 19/32 13/32 5/8 13/32 | 3/4 9/16 25/32 9/16 | 9/16 3/8 19/32 3/8 | 23/32 17/32 3/4 17/32 |

| See Notes 2 | 3 | 3 | 3 | |||||||||

NOTES :

- (1) Point of screw shall be tapered and fluted or slotted as illustrated above for the respective types. The flute on Type T screws shall have an included angle of 90° to 95° and the thread cutting edge located above the axis of screws. Tapered threads shall have unfinished crests, and the flutes or slots shall extend through the first full thread beyond taper except for Type F screws on which tapered threads may be complete at manufacturer’s option and flutes may be one pitch short of the first full form thread. Other details of taper and flute design shall be optional with the manufacturer, provided the screws meet the specified performance requirements.

- Where specifying nominal size in decimals, zeros preceding decimal and in the fourth decimal place shall be omitted.

- Screws of these nominal lengths and shorter shall have point taper lengths specified for short screws. Longer lengths shall have point taper lengths specified for long screws.

- For additional requirements, see lntroductory Notes and General Data, page H-13 and page H-18.